An Introduction to our Princess Carolina Protection Program:

Howdy, my name is Jules (pictured below) and I’m one of the archaeological conservation interns for summer 2023. The possibility of interning at The Mariners’ Museum and Park caught my attention as a graduate student and young museum professional interested both in maritime heritage and conservation. Working on Princess Carolina is allowing me to continue broadening my collections background and expand my conservation knowledge at a scale I’ve never experienced before.

Hiya, my name is Ariel McIntyre (pictured below) and I am from Canada. I am also here as an international summer intern. I was looking to expand my experiences as I surge forward into my conservation career and this exciting opportunity happened to cross my path. Working with Princess Carolina is giving me unique experiences in collections handling and cleaning on such a large scale. I am very excited to be a part of this project. Jules and I wrote this post together to update our readers on all the work that has been accomplished so far this summer!

Background

Princess Carolina, also known as the “Ronson ship,” was a South Carolina built transatlantic trading vessel in the 18th century. In 1729, the ship was damaged and eventually used as fill material during the land expansions of Manhattan in the mid-18th century. It was discovered during excavations for new development in 1982. Urgent salvage excavations were done in order to save a part of the ship, bringing 330 timbers from its bow and over 14,000 fill materials (Riess and Smith 2015).

Princess Carolina is the oldest surviving North American built merchant vessel. While not as well known as some of our warships, merchant vessels played a very important part in the economic and cultural productivity of developing nations. They engaged in trade, connecting continents, and allowing for economic and cultural transmissions during the colonial period. Merchant vessels were often targeted by pirates and, though Princess Carolina was no exception, as far as we know, the ship managed to successfully avoid them during its travels (Riess and Smith 2015).

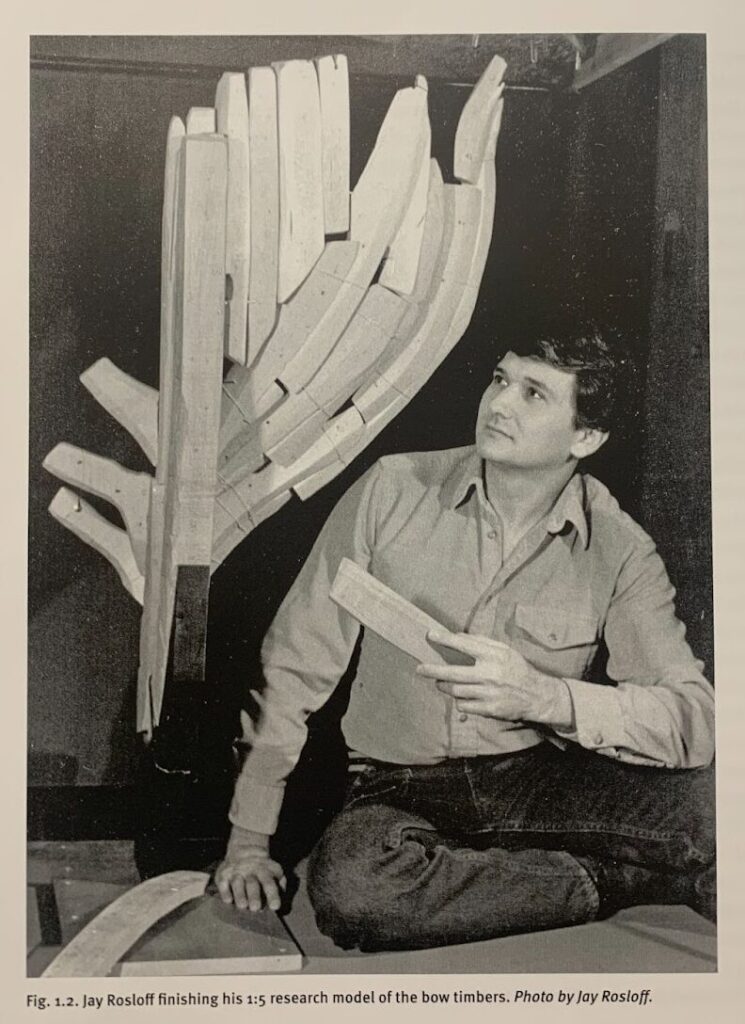

It is a unique ship, built a little differently than most we know. The builder definitely knew what the ship was supposed to look like, though it had a different method of going about things that was never written down with mixed American and European traits. Essentially, it is theorized that the ship’s designer did the math on paper first then slapped the ship together, which was not an uncommon thing to do at the time. The knots of the tree still visible in the wood and its asymmetrical shape, which in part helped identify it as Princess Carolina, are some evidence of this theory (Riess 2023).

After about a dozen years of cross-Atlantic service, the ship encountered a storm and managed to sail back to New York City for repair where it was docked and never left. There may have been a time where it was used as a floating warehouse before the ship was eventually used for fill as the Manhattan shoreline was extended (Riess and Smith 2015).

In 1982, during a renovation project on 175 Water Street, New York, Princess Carolina was discovered by construction workers. Archaeologists were called for a salvage excavation and, after study and partial conservation, over 300 of the timbers and the large collection of fill artifacts were entrusted to The Mariners’ Museum and Park in 1985.

In recent years, the Conservation team noticed precipitates forming on the wood believed to be acidification due to sulfur oxidation, in addition to an excess of the bulking solution polyethylene glycol (PEG) seeping from the wood. These are both common occurrences in recovered wooden shipwrecks, and have also been observed in ships such as Mary Rose and Vasa (Hocker 2018).

To prevent further deterioration and allow for future research and treatments of the timbers, this project, funded by The Bronze Door Society, is focusing on the documentation, cleaning, pest mitigation, rehousing, and establishment of a controlled storage environment for the timbers (Fleming et al. 2018).

Process

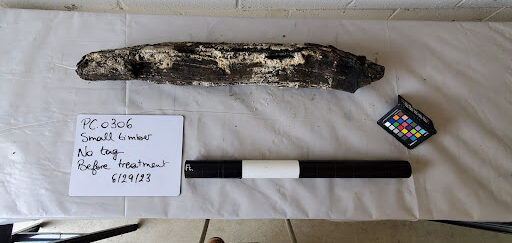

Each timber is photographed and inventoried before being moved to a table to be mechanically cleaned.

Cleaning consists in removing sulfur’s growth and PEG surplus as much as possible. With wooden skewers and dental tools, all the excess PEG, sulfur, and acidified wood are removed. Vacuums with HEPA filters are also used in the process.

The timbers are then moved onto pallets to wait for transportation to a walk-in freezer. Once a batch is finished, it is loaded onto a trailer and taken to the freezer.

The timbers are then stored in batches in a freezer set at -30℃ for five to seven days. After thorough research, the Conservation team chose this freezer set up to make sure any pests or potential mold are killed before the timbers move into its new climate controlled, and pest-free space. In the meantime, we work on cleaning and prepping the next batch for transport.

After time in the freezer, the batch is moved into the Batten Conservation Complex Workroom. The timbers defrost and are organized on large numbered shelves, inventoried, and ready for future research and treatment.

Challenges

While there are quite a few “small timbers’ that are more easily moved, there are also many timbers that are too heavy for us to lift with even several sets of hands. The stem, for example, is approximately 10 feet long and made of thick live oak. Live oak is one of, if not, the heaviest hardwoods in North America, so moving it in any way is a process.

Best practice is never moving an object more than is absolutely necessary, so to minimize its movement, the stem was gently lifted and lowered onto rolling dollies using an engine hoist. The process of moving “large timbers” onto the dollies is delicate and slow – it’s a heavy log! This method protects the object from damage while keeping the conservation team safe.

Using the hoist and straps, we lowered each end onto their own separate dollies, one at a time. This took a team of four people; two to help direct the ends onto the dollies, one to operate the crane, and another to observe in case anything went wrong and occasionally offer hands as needed. Will Hoffman, director of conservation and chief conservator at The Mariners’, took the lead on the procedure as he is certified for rigging and crane operation. The same procedure will be used for all the large elements of the bow.

So to recap: our “Princess Protection Program” involves the documentation, cleaning and relocation of Princess Carolina timbers from basement storage to a new climate controlled home. In labs around the Museum, our Conservation team is conducting research on mitigating the sulfur acidification of wood and testing potential preventative treatments for waterlogged wood. To learn more about these projects, check out the blog posts “Saving Princess Carolina: Acidification Research and Future Treatment Options” by Christina Atland and Lyndi Kiple’s “Big Bad Sulfur: Using Science to Find a Preventative Treatment.” For a more comprehensive history of Princess Carolina’s journey, we recommend both The Ship that Held Up Wall Street (2015) and Studying the Princess Carolina (2023) written by the lead archaeologist of the 1982 excavation, Dr. Warren Reiss.

Keep an eye out for more updates about Princess Carolina because this ship has a lot to share.

References:

Fleming, Hannah, Elsa Sangouard, and Will Hoffman. “Archaeological Assessment,

Stabilization, and Conservation Treatment Proposal for ‘Ronson’ Shipwreck Materials at The Mariners’ Museum and Park.” The Mariners’ Museum and Park, 2018.

Hocker, Emma. Preserving Vasa. London: Archetype Publications, 2018.

Riess, Warren. “The Ronson ship: The study of an eighteenth century merchantman excavated

in Manhattan, New York in 1982.” Dissertation, University of New Hampshire, 1987.

Reiss, Warren. Studying the Princess Carolina: the anatomy of the ship that held up Wall Street.

College Station: Texas A&M University Press, 2023.

Reiss, Warren and Sheli Smith. The Ship that Held Up Wall Street: the Ronson Shipwreck.

College Station: Texas A&M University Press, 2015.