The Monitor crew is busy with spring cleaning. Dry ice cleaning, that is. Last month we tackled Monitor‘s skeg assembly.

“What,” I can hear many people wondering, “is a skeg?”!

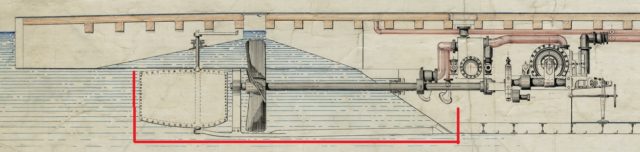

A skeg extends out the backend of a ship to stabilize and protect the propeller and rudder. Monitor’s skeg consisted of a 28 ft. long wrought-iron beam attached to the ship’s stern plate at one end. At the other end, there was a hole that allowed the rudder post to lock into the beam and swing freely. A Y-shaped bracket sat between the propeller and rudder. It bolted to the underside of the upper deck. The back end of the propeller shaft was mounted on the Y bracket, allowing it to spin freely.

Skeg tank work is always memorable as it involves early starts, long days, and a giant crane. We usually set aside three weeks for the project. We start by dismantling the ER (electrolytic reduction) treatment system and rinsing the tank down to neutral (iron is kept in high pH solutions to protect it).

Once the prep work is done, a 22-ton crane and flatbed truck are contracted to move the tank’s contents to the nearby “tank farm” (a fenced-in area that houses smaller tanks). As the objects are unloaded from the truck, we wrap them with soaker hoses, blankets, and plastic. Everything must stay wrapped and wet until all work is done and we can reset the tank.

The purpose of spending the day moving massive objects is to prepare them for dry ice cleaning. The frozen dry ice pellets act as an abrasive and remove corrosion and concretion from the wrought iron surfaces. This year marked the final round of dry ice cleaning for the skeg objects. If the solution’s chloride level doesn’t rise in the upcoming months, we will start rinsing them. And the next time they come out of the tank will be the last time! We will then start the process of drying and coating them to prepare for their eventual display and/or storage.

Check out the slideshow below for photos of the project and watch a video from moving day on our Facebook page!