Cannon Tools

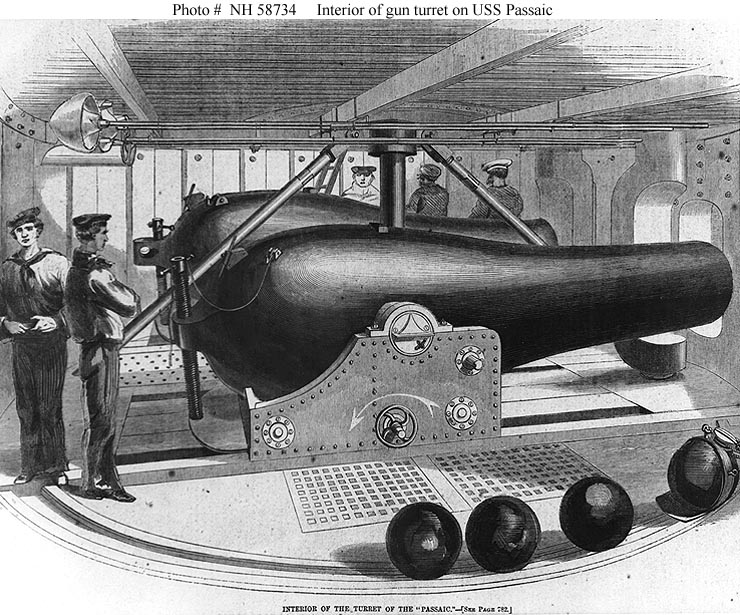

You’re probably familiar already with USS Monitor’s Dahlgren guns. They are a key part of the history of Monitor, and we have completed some significant conservation steps to finishing treatment on the Dahlgrens recently. What you are likely less familiar with are the tools that were used to maintain the Dahlgren guns while they were used on USS Monitor.

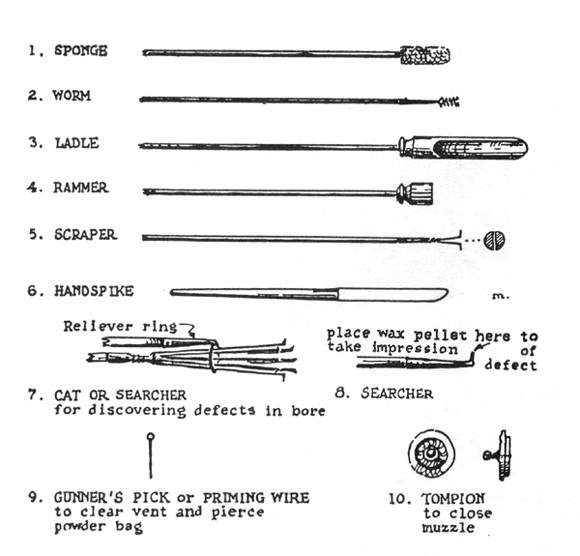

In the image above you’ll see illustrations of several historic cannon cleaning and loading tools. 1) The sponge would be dipped in water, and run down the barrel of the cannon to extinguish sparks in the bore after firing. 2) The worm cleaned unburned fragments of cloth powder bags from the bore. 3) Ladles were originally used to load powder, but after cartridge bags came into use, they were used to extract loads from the muzzle. 4) The rammer sealed cartridge and ball in place in the barrel. 5) The scraper and searchers were used to clean the gun. 6) The handspike helped to move the gun carriage and to adjust the gun’s elevation. (From Albert Manucy, Artillery Through the Ages (Government Printing Office, 1949). All of these tools would be used to maintain the Dahlgren guns on Monitor and generally used each time the cannon was fired.

Monitor Gun Sponge

We have several examples of these gun tools in the Monitor collection, specifically, worm, sponge, and rammer. I have been working on one of the gun tools, a combination sponge and worm tool. This tool has a wood body, with an iron handle, and the majority of the handle was removed during excavation. It also has a copper alloy worm attached to the end. When it was in use, the wooden body would have been wrapped in fabric, so that it would retain moisture when dunked in water before cleaning the cannon barrel. The gun tool is also coming to the end of treatment, so I thought I would share with you all the process it has been through.

Condition

When I first started conservation on the gun tool, it was covered in compressed mud and marine growth from when it was buried on the ocean floor. This meant it was impossible to see if any of the fabric that would have been wrapped around the wood remained. Even though we could tell it was a gun sponge with a worm attached, it was difficult to tell what kind of condition the wood and metal pieces were in. We x-rayed the gun sponge, which allowed me to see how degraded the wood was, and how far the metal components extend into the wood body.

The x-ray showed me that while some parts of the wood were very degraded, the majority of it was stable and in good shape. The x-ray also showed me that the worm is held in place inside the wood with a pin, as is the iron handle. So both metal components would be nearly impossible to separate from the wood body, and I needed to conserve the object whole. This makes for extra complications because the treatments for wood and metal are very different. In fact, some metal treatments can be damaging to wood and vice versa. So I knew I needed to look into some alternative options for the gun sponge.

Surface Cleaning and Examination

However, the first step was a clear choice–clean the mud and marine growth off the surface. For this process, I used a combination of pneumatic tools and an ultrasonic dental scaler. The dental scaler is the same tool the dentist uses to clean your teeth, and with adjustable water jets and sonic cleaning, it also makes a great tool for cleaning waterlogged organics.

Cleaning the surface confirmed what I saw in the X-ray. The wooden body of the tool is heavily degraded on one side, but the other is fairly intact and stable. I found that the iron handle was attached to the wood body with a very degraded cast iron plate and four copper-alloy screws. But most exciting of all, I found that the iron handle was wrapped in textile! AND it was still in fairly stable condition. I knew I had to ensure the textile was well preserved in my treatment.

I’ll return to the gun tool treatment in Part II, were I talk about how I protected the textile during treatment, and how I adjusted treatment steps to preserve both the metal and organic components. See you next week!