The Monitor’s clock movement was in amazingly good condition after 139 years in saltwater, due to many of the parts being made of high quality brass and copper nickel alloys.

The use of nickel in some of the components was verified by elemental analysis performed at the College of William and Mary materials characterization laboratory at the Jefferson Laboratories Applied Research Center in Newport News. This analysis provided valuable guidance in selecting the most appropriate conservation treatment for these parts. The delicate springs, screws, and gear shafts (called arbors) made of steel did not fare so well, however, and had completely rusted away apart from a few preserved remnants of the main spring.

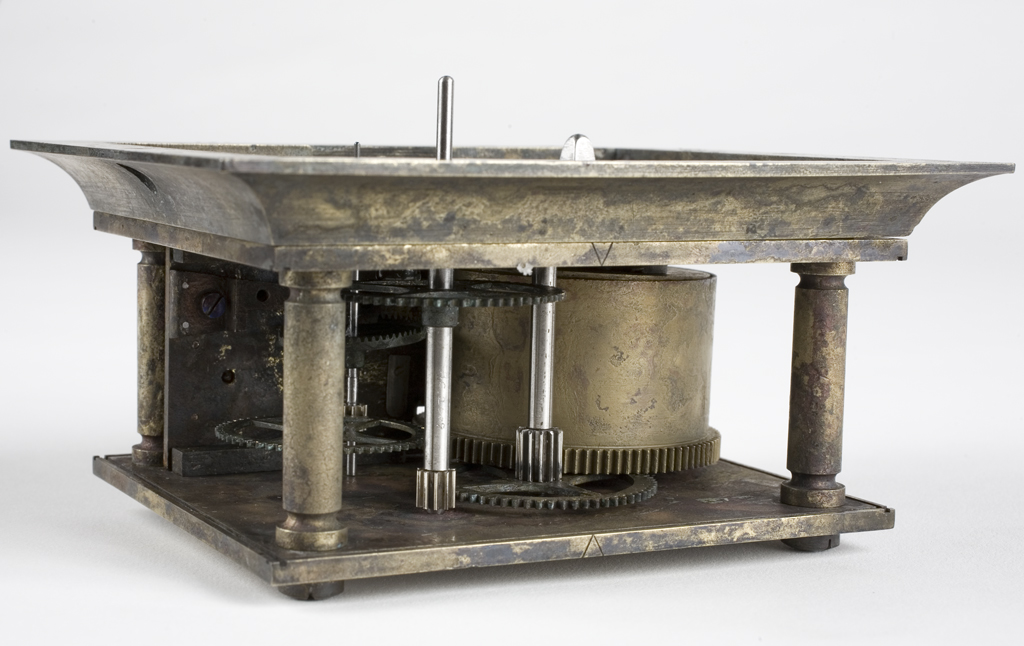

After thorough cleaning to remove calcareous crusts, the clock movement’s components were treated with electrolytic reduction to remove corrosion and salts before drying and coating with a clear acrylic resin to protect their surfaces. In order to properly reassemble the clock movement and represent it in as close as possible to its original form, conservators and curators at The Mariners’ Museum elected to work with Roger to make modern parts including screws, fittings, and arbors to replace those which had been lost to corrosion.

This was no small task as Roger can attest: “The arbors themselves required a few false starts because a small diameter rod (1/8″ or less) is extremely difficult to machine, even when using a follower on the lathe. The slender rod deflects during machining and doesn’t allow a smooth finish to be produced. This problem led to my method of machining the arbors in segments that were pressed together into the finished arbor.” Modern replacement parts made by Roger were carefully documented and marked to avoid confusion with the originals.

The addition of newly made parts allows the Monitor’s clock movement to be visually complete, but was not done with the intention of making it possible for the clock to run. While it might be technically possible, making the movement operate would require alteration to the original historic parts and would lead to wear and tear on the components. Instead, the surviving parts will be preserved, supported by the carefully made modern replica components.

The result is a complete presentation of the inner workings of the Monitor’s clock which looks very much like it did when it kept accurate time during the Battle of Hampton Roads and counting the Monitor’s last fateful moments before slipping beneath the waves.

Look for Monitor’s clock movement on display at the USS Monitor Center!